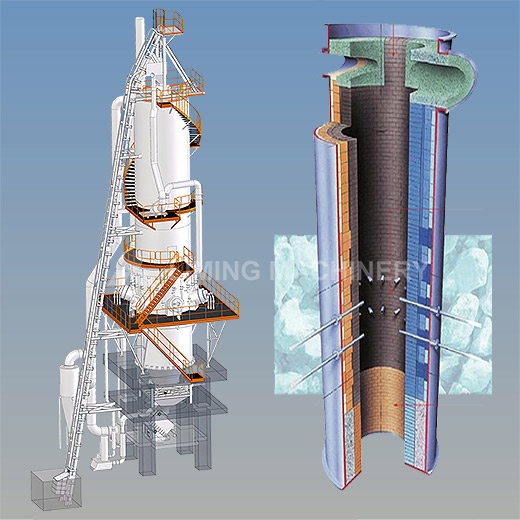

Shaft Kiln

Shaft kiln refers to vertical shaft kiln for lime. Liming Machinery's vertical lime kiln is a modern facility that integrates environmental protection and energy-saving functions with a high degree of mechanization and automation. By adopting advanced technologies, it efficiently utilizes low-cost energy sources, particularly converting environmentally polluting gases (such as converter gas, blast furnace gas, and calcium carbide furnace exhaust) into primary energy, thereby transforming waste into valuable resources.

Calcination Temperature: 1100±50℃

Applications:

Suitable for metallurgy, building materials, calcium carbide, nano-calcium carbonate, aerated concrete, sugar refining, and other industrial sectors.

Capacity: 50-400(t/d)

Input size: 30-80 mm / 80-120 mm

Product Details

Performance Advantages

Cooling air injected from the kiln bottom preheats through product cooling, then rises to support combustion in the calcination zone, cutting fuel consumption via self-sustaining heat recycling.

Material descends by gravity with minimal surface abrasion, reducing wear rate. Service life reaches 6-10 years under normal operation.

The kiln supports mixed-firing (lump coal/coke), gas-firing (high-value fuels like natural gas or low-value gases including converter/blast furnace gas), and oil-firing (heavy oil/diesel), ensuring adaptability to diverse energy sources.

Vertical shaft configuration, steeply-angled skip hoist feeding, and tightly-arranged functional zones collectively minimize ground space requirements.

Reduced steel processing components lower machining costs, while simplified installation and refractory lining minimize construction expenses.

Working Principle

The Shaft kiln has a cylindrical structure where materials are fed from the top and discharged from the bottom. The interior of the kiln is divided from top to bottom into three zones: the preheating zone, the calcination zone, and the cooling zone. In the preheating zone, flue gas is used to preheat the materials; in the calcination zone, fuel combustion provides the heat required to complete the calcination process; in the cooling zone, the materials exchange heat with blown-in cold air for cooling, and the heated air then enters the calcination zone to support combustion.

The movement of materials inside the kiln is driven by calcination-induced shrinkage and discharge from the bottom. After calcination is completed, the materials are cooled to approximately 60°C above ambient temperature, unloaded outside the kiln through ash dischargers and sealing valves, and then elevated, screened, and stored in different silos according to particle size.

Combustion air is blown into the bottom of the kiln by Roots blowers, while an induced draft fan creates a slight negative pressure (approximately -10 Pa) at the top of the kiln, ensuring smooth airflow and stable calcination. The flue gas is treated through dust removal and purification before being discharged up to standard through the chimney.

WhatsApp

WhatsApp

Leave message

Leave message