The supplementary cementitious materials (SCM) production line serves as a green nexus linking solid waste, technology, and construction. It transforms industrial by-products such as fly ash and slag into high-reactivity materials with controlled performance through intelligent grinding and precise homogenization. These materials ultimately become critical components in major projects like super high-rises and cross-sea bridges, playing a central role in enhancing durability and reducing carbon emissions.

LM vertical mill is a special equipment for scm powdering. It integrates crushing, drying, grinding and grading transportation. The system is simple and the layout is compact. It covers an area of about 50% of the ball mill system and can be arranged in the open air. Therefore It can greatly reduce investment costs; and the grinding roller directly grinds the materials on the grinding disc, which has low energy consumption and saves 30% to 40% of energy compared with the ball mill system.

Due to the function of the hydraulic device and the limiting device, the gap between the grinding roller and the grinding disc can be adjusted to a constant gap with wear, thereby increasing the grinding pressure and stabilizing the output.

Equipped with a new grinding roller sealing device, the sealing is more reliable and no sealing fan is required.

The grinding roller shaft is lubricated with proprietary thin oil and adopts cyclic forced lubrication, which is stable and reliable and has a long service life.

The powder separator adopts frequency conversion control, and the fineness adjustment is convenient and fast, and the particle size is stable.

| Model | capacity(t/h) | Moisture | Specific surface area |

| LM17-2N | 7-11 | 15% | ≧420㎡/㎏ |

| LM19-2N | 9-13 | ||

| LM21-2N | 11-15 | ||

| LM24-2N | 13-18 | ||

| LM28-2N | 22-28 | ||

| LM35-3N | 50-60 | ||

| LM42-4N | 70-85 | ||

| LM46-4N | 90-110 | ||

| LM54-4N | 130-150 |

Note: The above processing capacity refers to the reference value when the slag grindability (Bond) index is ≤23KWh/t.

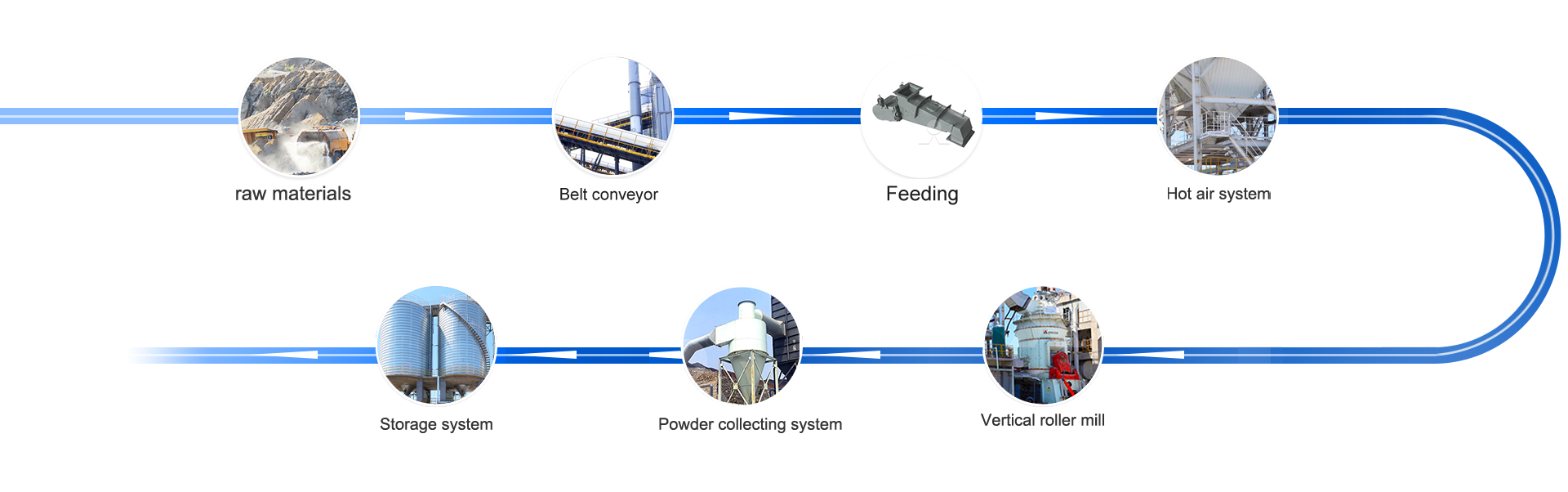

The core process—“Grinding–Separating–Collecting–Homogenizing”—forms a closed-circuit loop, enabling continuous, efficient, and high-quality production.

Raw materials (e.g., fly ash, slag) are batched and proportioned, then elevated to a vertical roller mill for efficient grinding and simultaneous drying. The ground material is carried by air flow to a dynamic separator, where qualified fine powder is selected, while coarse particles are returned to the mill for regrinding. The qualified fines are collected by a dust collector, stored and homogenized in a blending silo, and finally dispatched via packaging or bulk loading systems.

Professional answers

Customer service

Tailored

solution

Assist in formulating construction plan

Installation guide and debugging

Regular testing and visit

Copyright © LIMING Machinery CO., LTD. All rights reserved Privacy Policy