The clinker calcining system serves as the "heart" of a modern cement plant. It is an integrated

high-temperature process system that converts uniformly

proportioned raw meal powder into cement clinker. Modern systems are centered on suspension

preheating, precalcination, and high-efficiency cooling

technologies.

The standard configuration of the clinker calcining system has a daily production capacity of

700-2500 tons, while smaller production lines have a capacity

of200-500 tons per day.

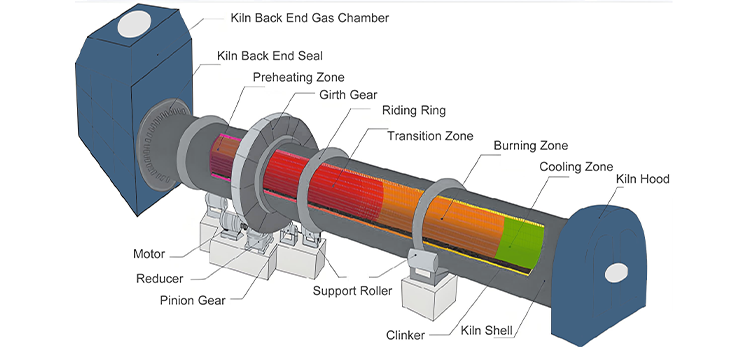

The clinker calcination system employs a low-pressure-loss single-series five-stage cyclone preheater and a new dry process configuration system consisting of a preheater, rotary kiln, and grate cooler. The calcium carbonate decomposition rate of the feed material can reach 90%.The rotary kiln uses a two-stage support short kiln, effectively reducing equipment costs by 15-25%.

Ⅰ.The preheater uses tertiary air drawn directly from the kiln head hood.

Ⅱ.Clinker cooling utilizes a controllable airflow grate cooler. The clinker temperature entering the cooler is 1371℃, and the temperature exiting the cooler is 65℃ + ambient temperature. The thermal efficiency of the cooler system is approximately 70%. A clinker crusher is located at the cooler outlet, and the clinker exiting the crusher is conveyed to the clinker storage silo via a chain bucket conveyor. A portion of the exhaust gas from the grate cooler is used as a heat source for drying the coal mill, while the majority is purified by an electrostatic precipitator before being released into the atmosphere, with a dust emission concentration ≤30mg/Nm3.

Ⅲ.The clinker is stored in a prototype cone-top tent-style silo, with a storage capacity of 5-10 days. After being unloaded from the silo bottom by the unloading device, the clinker is conveyed by a belt conveyor to the clinker batching bins at the cement batching plant.

Application of Calcination in Practical Cases

Calcination in Cement Production

Raw meal calcination is the core process in cement production, aiming to transform the uniformly blended raw meal (limestone, clay, iron ore, etc.) into clinker through high-temperature firing.

Working Principle of Calcination

First, the powdered raw meal undergoes efficient heat exchange with the

hot gases from the kiln outlet in the suspension preheater and precalciner

system. This process achieves over 85% pre-decomposition of calcium

carbonate before the material enters the kiln, significantly reducing energy

consumption.

Subsequently, the material enters the rotary kiln, where it undergoes

decomposition and solid-state reactions before final sintering in the burning

zone at approximately 1450°C. This forms cement clinker with tricalcium

silicate as the core mineral.

Finally, the incandescent clinker is rapidly cooled in the grate cooler. The

recovered hot air is recycled back into the system, while the cooled clinker

is transported to the cement grinding plant as the final product.

Technical Support

1.2 Million

Square Meters Production Base

689 Sets

Of Precision Manufacturing Instruments

Nearly 300

National Patents

Founded in 1987, Liming heavy industry, ltd is headquartered in Zhengzhou National High-tech Industrial Development Zone. It owns six major equipment industrial parks with a total area of 1.2 million square meters. All products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification. As a one-stop solution provider for grinding mill, our products and services have benefited more than 20,000 customers in more than 180 countries and regions around the world, forming a good situation of rational utilization of resources, energy saving and emission reduction, ecological environmental protection and harmonious development of the environment.

Copyright © LIMING Machinery CO., LTD. All rights reserved Privacy Policy