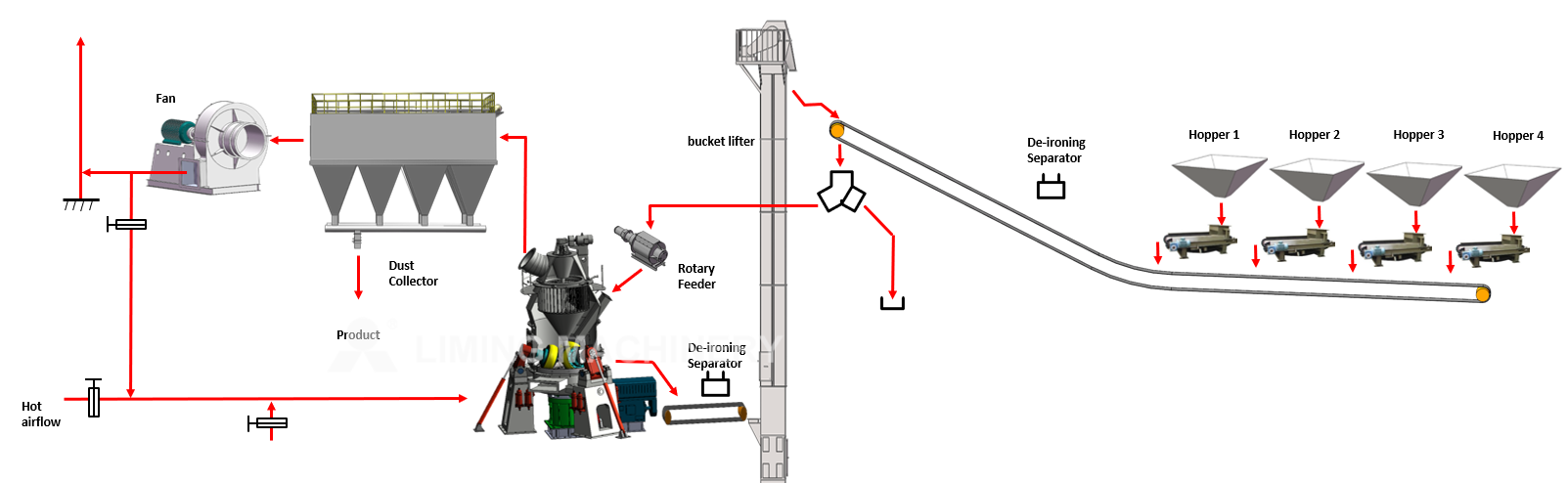

Due to the complex composition, high moisture content, and significant differences in grindability of raw materials, Liming Heavy Industry has spent over twenty years developing the LMR energy-saving grinding equipment, integrating drying, grinding, grading, and conveying. This equipment boasts advantages such as high grinding efficiency, low power consumption, large feed particle size, easily adjustable product fineness, simple process flow, small footprint, low noise, low dust emission, easy operation and maintenance, low operating costs, and low consumption of wear-resistant materials. The product's overall performance reaches international advanced levels, meeting the needs of large-scale, intelligent, and intensive industrial grinding. The maximum production capacity can reach 550 t/h, meeting the raw material supply needs of cement production lines with a capacity of 200-2500 t/d.

WhatsApp

WhatsApp

Leave message

Leave message