Rotary Kiln

Product Introduction: Cement rotary kiln is a type of rotary kiln commonly used for the production and calcination of cement clinker. Currently, the cement rotary kiln produced by our company is mainly a dry process production line equipment for cement clinker. According to different cement clinker production processes, this product is divided into hollow dry process kiln, kiln with preheater, and external decomposition kiln. There are sixteen models with cylinder diameters between 2.5m and 4.3 meters, which can meet the daily production range of 180-3200 tons of dry process clinker calcination.

Applications:

Suitable for cement plants and clinker production lines.

Capacity: 200-2500(t/d)

Performance Advantages

It can evenly heat the material during calcination, ensuring stable product quality

The main transmission system utilizes advanced AC variable frequency speed control technology, offering energy efficiency, environmental friendliness, wide speed regulation range, high efficiency, precise speed control, and stable operation.

The base welding of both the single supporting roller device and the thrust roller device has been completed. After vibration stress relief treatment to eliminate welding stresses, the installation accuracy and reliability of the entire machine can be improved.

The kiln head and tail sections have undergone comprehensive structural redesign, effectively resolving common issues of return material at the kiln end and dust leakage, thereby ensuring smoother and more natural material conveying.

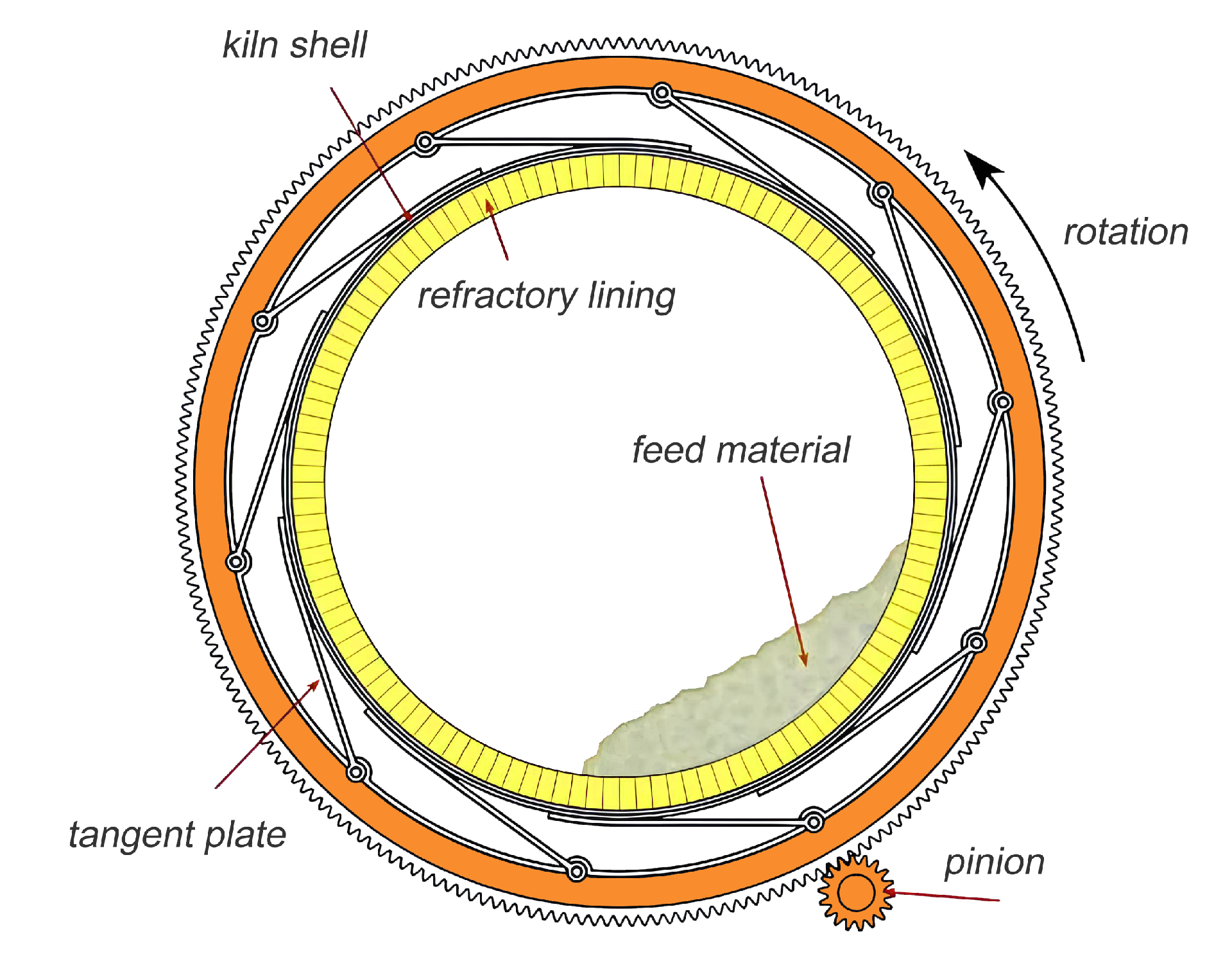

Working Principle

Material is fed into the kiln from the kiln tail (higher end). Due to the inclination and slow rotation of the cylinder, the material moves forward gradually while rolling axially and radially. Fuel is injected into the kiln through the burner at the kiln head (lower end) for combustion. Heat is transferred to the material through radiation and conduction. During its movement, the material forms a liquid phase, generating minerals such as tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite. After completing the sintering process, clinker is formed and discharged from the kiln head.

WhatsApp

WhatsApp

Leave message

Leave message