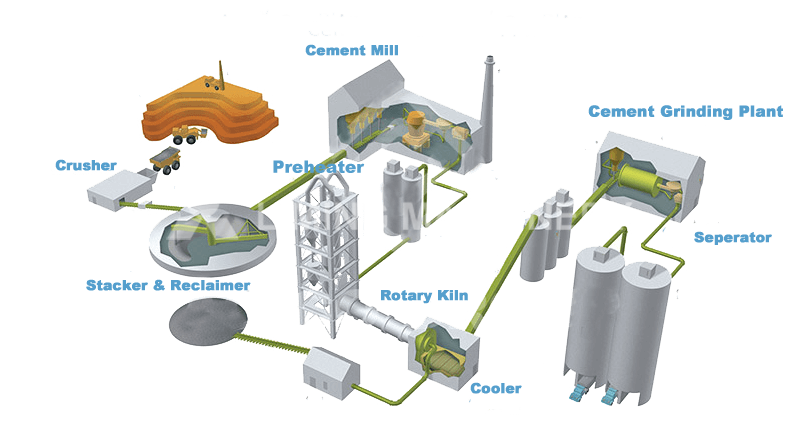

The main cement used daily is silicate cement: limestone and clay are the main raw materials, which are crushed, batched, and ground into raw meal, then fed into a cement kiln to form clinker. The clinker is then ground with an appropriate amount of gypsum (sometimes mixed materials or admixtures are also added). The production method is as follows:

Limestone Crushing and Pre-homogenization

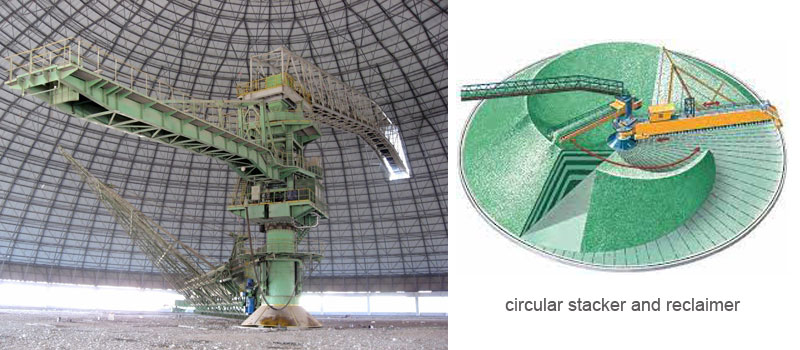

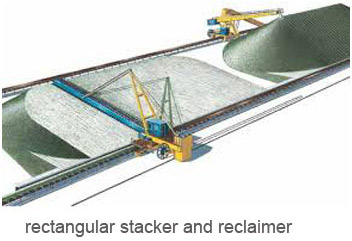

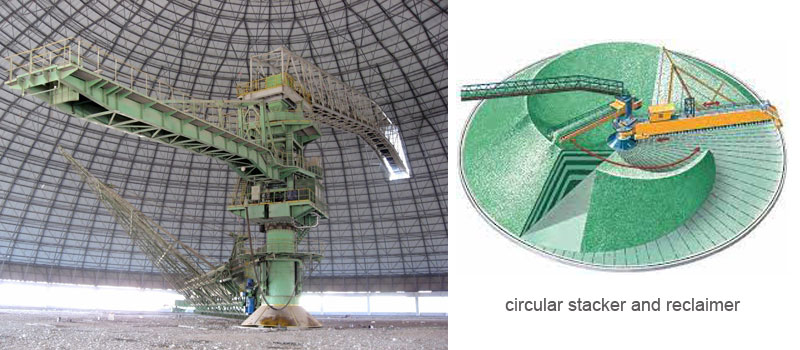

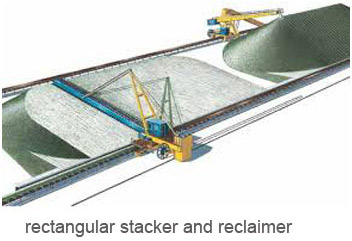

The main raw material, limestone, is first fed into a crusher for crushing to a certain fineness, and then conveyed to the limestone pre-homogenization stockpile via a belt conveyor. The pre-homogenization stockpile has a storage capacity of 5-7 days. A side-mounted cantilever stacker is used for back-and-forth stacking, and a bridge-type scraper reclaimer is used for end-face material collection. The collected limestone is then conveyed to the limestone silo of the raw material batching station via a belt conveyor.

Preparation and Pre-homogenization of Auxiliary Materials and Fuel

Clay, sandstone, and other auxiliary materials that have passed testing, along with fuel coal, are crushed separately and then transported by belt conveyor to the auxiliary raw material and coal pre-homogenization stockpile for storage.

Raw Material Batching Station

The raw material batching station is equipped with batching bins for limestone, clay, and auxiliary materials 1 and 2. Each material originates from the pre-homogenization stockpile of its respective raw material. Each raw material is metered and batched according to the batching ratio, then transported by belt conveyor to the raw material mill inlet for raw meal grinding.

Raw Material Grinding and Waste Gas Treatment

The raw material grinding adopts a vertical mill system, utilizing a portion of the low-temperature waste gas discharged from the kiln tail as a drying heat source. The material is ground and dried inside the mill. Lumps falling from the vertical mill's air ring are returned to the mill by a belt conveyor and bucket elevator for further grinding. Qualified raw meal powder is collected in a cyclone separator with the airflow from the mill, and then sent to the raw meal homogenization silo via an air conveying chute and bucket elevator. The remaining waste gas discharged from the kiln tail is humidified and cooled by a humidification tower before entering an electrostatic precipitator along with the mill exhaust gas. After purification by the electrostatic precipitator, it is discharged into the atmosphere.

Raw Meal Homogenization and Raw Meal Feeding into the Kiln

A raw material homogenization silo is set up, storing 2-3 days' worth of raw material consumption. Homogenization is mainly achieved through gravity cutting within the silo and stirring in the mixing bin. The mixing bin also serves as the kiln feed bin, equipped with a load sensor and an air filling device. A flow control valve and a solid flow meter are installed below the bin to meter and regulate the kiln feed. The metered raw material is then transported to the kiln tail preheater via an air conveying chute and a bucket elevator.

Clinker Calcination System

Clinker calcination employs a low-pressure-loss single-series five-stage cyclone preheater and a new dry-process configuration system consisting of a decomposition furnace, rotary kiln, and grate cooler. The calcium carbonate decomposition rate of the feed material can reach 90%.

The rotary kiln uses a two-stage support short kiln, effectively reducing equipment costs by 15-25%.

The decomposition furnace uses tertiary air drawn directly from the kiln head hood.

Clinker cooling utilizes a controllable airflow grate cooler. The clinker temperature entering the cooler is 1371℃, and the temperature exiting the cooler is 65℃ + ambient temperature. The thermal efficiency of the cooler system is approximately 70%. A clinker crusher is installed at the cooler outlet, and the clinker exiting the crusher is conveyed to the clinker storage silo via a chain bucket conveyor. Part of the grate cooler exhaust gas is used as a heat source for coal mill drying, while most of it is purified by an electrostatic precipitator before being discharged into the atmosphere, with a dust emission concentration ≤30mg/Nm3.

Clinker Storage and Transportation:

The clinker is stored in a prototype cone-top tent warehouse with a storage capacity of 5-10 days. After being unloaded from the bottom of the warehouse, the clinker is conveyed by a belt conveyor to the clinker batching silo of the cement batching station.

Raw Coal Storage, Crushing, and Pre-homogenization:

Purchased raw coal is transported to the plant by truck and unloaded into the raw coal stockpile. It is then unloaded into the receiving hopper by a bucket truck and crushed by a ring hammer crusher. The crushed coal is conveyed by a belt conveyor to the raw coal pre-homogenization stockpile. The removed raw coal is conveyed by a belt conveyor to the raw coal silo of the coal mill.

Pulverized Coal Preparation System:

Coal from the homogenization stockpile is conveyed to the vertical pulverized coal mill. The particle size of the raw coal entering the mill is ≤25mm, and the moisture content is ≤10%. The fineness of the pulverized coal is ≤10% on an 80μm sieve, and the moisture content of the pulverized coal exiting the mill is ≤1%.

The coal mill is located near the kiln head, using the exhaust gas from the grate cooler as a drying heat source. Raw coal is fed into the mill via a speed-regulating quantitative feeder under the raw coal silo for drying and pulverization. The dried and pulverized coal powder is then classified by the classifier in the airflow mill. The separated coarse powder falls to the grinding disc for secondary grinding, while the qualified powder and exhaust gas enter a baghouse dust collector. The collected coal powder is then sent to the finished coal powder silo. The exhaust gas, purified by an explosion-proof pulse bag filter, is discharged into the atmosphere via a fan. The dust emission concentration is ≤30mg/Nm3.

Measuring devices for kiln and decomposition furnace coal powder are installed under the coal powder silo. Accurately measured coal powder is then pneumatically conveyed to the kiln head burner and decomposition furnace.

Cement Batching System

Generally, the incoming gypsum blocks are relatively large. After being crushed by a crusher, they are transported to the cement batching system silos along with the clinker and mixed materials from the clinker silo. Speed-regulating belt scales are used for metering under the silos, and the batching is automatically controlled by a computer. The batching material is conveyed to the cement grinding station by a belt conveyor and elevator for grinding.

Cement Grinding Station

The cement grinding system adopts a combined extrusion closed-circuit grinding system consisting of a roller press, a V-type classifier, a ball mill, and an O-Sepa classifier. The mixture from the cement batching system is fed into the V-type classifier via a conveyor. The coarse material separated by the V-type classifier returns to the roller press, while the finer material is separated by airflow into a cyclone separator. The separated fine powder is then fed into the mill for grinding. The mixture can also be directly fed into the mill for grinding. The material exiting the mill is fed into the O-Sepa classifier via an elevator and chute. The coarse material after separation returns to the mill for further grinding, while the fine powder is carried by airflow into a high-concentration bag filter. After being collected by the high-concentration bag filter, it is used as the finished product and then conveyed to the cement silo for storage via an air conveying chute and elevator. The gas exiting the high-concentration bag filter is discharged into the atmosphere, with an emission concentration ≤30mg/Nm3. The exhaust gas from the V-type air classifier is partially returned to the V-type air classifier via a circulating fan, and partially discharged after dust collection treatment, with an emission concentration ≤30mg/Nm3.

Cement Storage and Bulk Handling

Cement storage is provided in 4-6 silos, with a total storage capacity of 5-10 days. Each silo is equipped with a pressure-reducing cone and an air-filling device, supplied by a Roots blower. Cement leaving the silos is conveyed to the cement packaging system via a bottom unloading device, an air conveying chute, and a bucket elevator.

Cement Packaging

The packaging workshop is equipped with 6 or 8-nozzle rotary packaging machines, each system with a capacity of 60-90 t/h. Bagged cement in the plant area is unloaded into the finished cement warehouse via a belt conveyor, or can be directly loaded onto trucks by a mobile bagged cement loading machine.

Auxiliary Systems

The entire plant is equipped with supporting facilities such as an air compressor station, cooling and circulating water station, maintenance workshop, central laboratory, and power distribution room, providing a stable supply of auxiliary media for continuous production.

The plant has one compressed air station, which is equipped with four air compressors with a discharge capacity of 20 m3/min and a discharge pressure of 0.8 MPa to supply air to various air-consuming points, one of which is on standby.

.jpg)

WhatsApp

WhatsApp

Leave message

Leave message