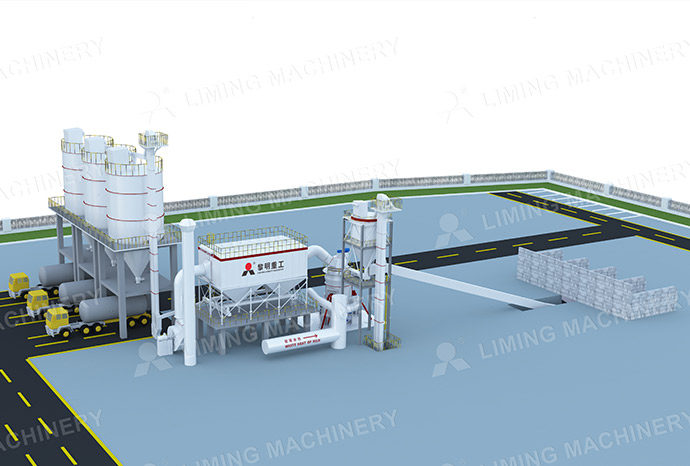

Clinker Vertical Mill

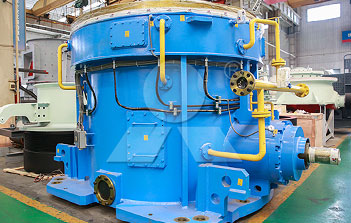

The vertical roller mill is a key equipment used for grinding cement clinker. Its main structure consists of a classifier, grinding roller device, grinding disc device, pressure device, reducer, electric motor, housing and other parts.This equipment has the advantages of high grinding efficiency, large drying capacity, easy adjustment of product fineness, low noise, low power consumption, simple process flow, low wear consumption, and low operating costs.

Applications:

It is widely used in industries such as cement, electricity, metallurgy, and chemical engineering.

Capacity: 7-200T/H

Input moisture: < 15%

Product Details

Performance Advantages

The equipment integrates crushing, drying, grinding, and graded conveying, with a simple system, compact layout, small footprint, and can be arranged outdoors, saving a lot of investment costs.

(1) Equipped with an automatic control system, it can achieve remote control and is easy to operate. (2) Equipped with a limit device to prevent direct contact between the roller sleeve and the grinding disc liner, it avoids destructive impact and violent vibration. (3) By inspecting the oil cylinder, flipping the transmission arm, replacing the roller sleeve and lining plate, it is convenient and fast, reducing losses caused by downtime.

The grinding rollers directly crush and grind the material on the grinding disc, reducing energy consumption and operating costs. Low wear consumption: During operation, the grinding rollers do not directly contact the grinding disc. The grinding roller and lining plate are made of wear-resistant materials, which have a long service life and low wear consumption.

The hot air introduced into the mill from the outside comes into full contact with the powder material inside the mill directly and repeatedly, with a strong drying ability. It can save one dryer for the mill system and save energy. By adjusting the temperature of the hot air, it can meet the requirements of materials with different moisture levels.

(1) Due to the short residence time of materials in the mill, it is easy to detect and control the particle size and chemical composition of the product, reducing repeated grinding and stabilizing product quality. (2) The product contains low iron content and the mechanical wear iron is easy to remove. When used for grinding white or transparent materials, the product has high whiteness and clarity.

With minimal vibration and low noise, the equipment is sealed as a whole, and the system operates under negative pressure without dust overflow. The environment is clean and meets national environmental protection requirements.

Working Principle

The main motor drives the grinding disc to rotate through the reducer, and at the same time, air enters the mill from the air inlet. The material falls into the center of the grinding disc through the screw feeder. Under the centrifugal force, the material moves uniformly from the center to the edge of the grinding disc. When passing through the grinding roller area on the grinding disc, it is grinded by the grinding roller, and large pieces of material are directly grinded. Fine particles are squeezed and form a material layer for inter particle grinding. The grinded material continues to move towards the edge of the grinding disc until it is carried away by the strong airflow at the wind ring, while larger particle materials fall back onto the grinding disc for further grinding. When the material in the airflow passes through the upper classifier, the coarse particles return to the grinding disc for grinding under the action of the classifier. The qualified fine powder is discharged from the grinding with the airflow and collected by the system's powder collector. The collected powder is the product of vertical mill. When iron blocks and other impurities mixed with the material move to the edge of the grinding disc, they cannot be blown up by the wind due to their heavy weight and fall into the lower chamber of the mill. They are scraped into the slag discharge outlet and discharged outside the machine by the scraper plate installed at the bottom of the grinding disc.

WhatsApp

WhatsApp

Leave message

Leave message