Twin-shaft kiln

The twin-shaft kiln represents the most advanced lime kiln technology currently available. It operates by alternating the calcination process between two interconnected shafts, producing lime with high reactivity and superior quality that meets the requirements of most market users. Additionally, its capability to utilize multiple fuel types makes it widely suitable for large-scale lime production enterprises.

Applications:

Medium to large-scale lime plants with stringent quality requirements.

Product Details

Performance Advantages

Based on the design of "alternating calcination + waste heat recovery," the thermal efficiency reaches 75%-85%, far exceeding that of single-heat vertical kilns (50%-60%); fuel consumption per unit product is low. Taking lime calcination as an example, the fuel consumption per ton of active lime is only 80-120m³ (natural gas) or 120-150kg (pulverized coal), which is 20%-30% lower than that of single-heat vertical kilns.

Employs a two-stage purification system of 'cyclone dust collector + bag filter,' achieving dust emission concentration ≤10mg/m³, far below the national emission standard (30mg/m³); the low-temperature combustion air and short flame design during combustion ensure NOx emission concentration ≤300mg/m³, meeting standards without the need for additional denitrification equipment.

Can process various raw materials (limestone, dolomite, magnesite, etc.), with a wide range of raw material particle sizes (20-80mm), and strong tolerance to fluctuations in raw material composition (CaCO₃ content fluctuations of ±5% do not affect finished product quality). Alternating calcination mode ensures a uniform temperature field within the kiln (temperature difference ≤50℃), resulting in high finished product activity (lime activity ≥300ml/4N-HCl), low under-burning/over-burning rate (≤5%), and superior quality stability compared to rotary kilns (under-burning/over-burning rate ≤8%).

30%-50% of the floor space of a rotary kiln of the same capacity (e.g., a 300-ton-per-day lime production line requires approximately 800㎡), reducing civil engineering investment by 20%-30%.

The equipment has a simple structure (no complex transmission components), resulting in a purchase cost 40%-50% lower than a rotary kiln, and a short installation period (3-4 months), making it suitable for rapid production deployment by small and medium-sized enterprises.

Alternating operation mode eliminates continuous high-temperature zones, extending the kiln lining (refractory bricks) service life to 3-5 years, far exceeding that of rotary kilns (1-2 years); core components (reversing valves, burners) have a low failure rate, with annual operating time exceeding 8000 hours.

Working Principle

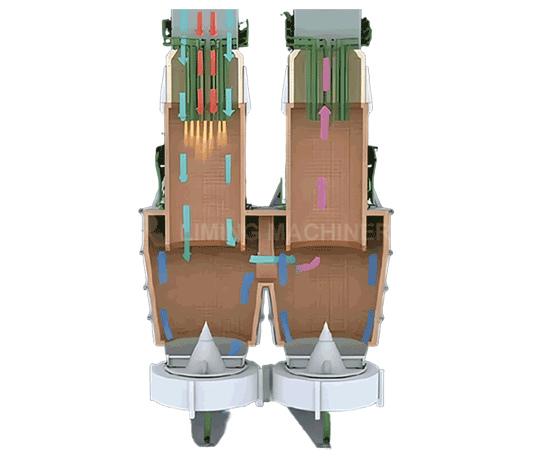

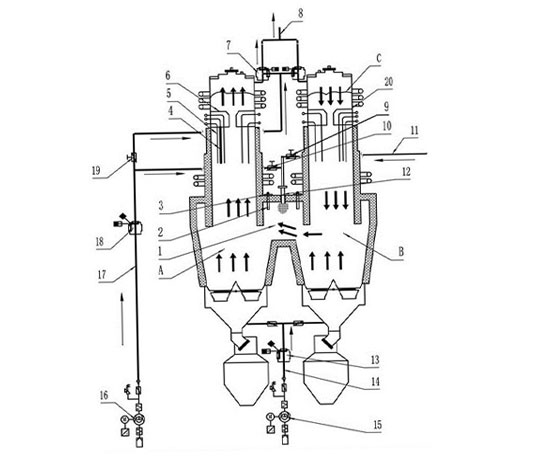

The twin-shaft kiln calcines limestone using two chambers. Shaft A and Shaft B are connected at the bottom of the calcination zone, and the material moves downward through both shafts. During calcination in Shaft A, combustion air and fuel flow parallel to the material in Shaft A, allowing the hot flame to come into contact with the cooler, highly endothermic material. Conversely, the relatively lower-temperature combustion gases interact with the progressively calcined material, achieving uniform calcination conditions and high thermal efficiency. The combustion products and CO₂ released from the material decomposition pass through the connecting channel into Shaft B. At this stage, Shaft B acts as a regenerative chamber, where the limestone inside absorbs heat from the exhaust gases, while the exhaust gases are cooled to a relatively low temperature. The material stores heat, which is then used to preheat the combustion air for the next cycle. In this configuration, Shaft A serves as the combustion shaft, reflecting the parallel flow characteristic, while Shaft B functions as the regenerative shaft with heat storage properties. In the next cycle, the roles alternate: Shaft A becomes the regenerative chamber, and Shaft B becomes the combustion shaft. This enables continuous limestone calcination.

WhatsApp

WhatsApp

Leave message

Leave message