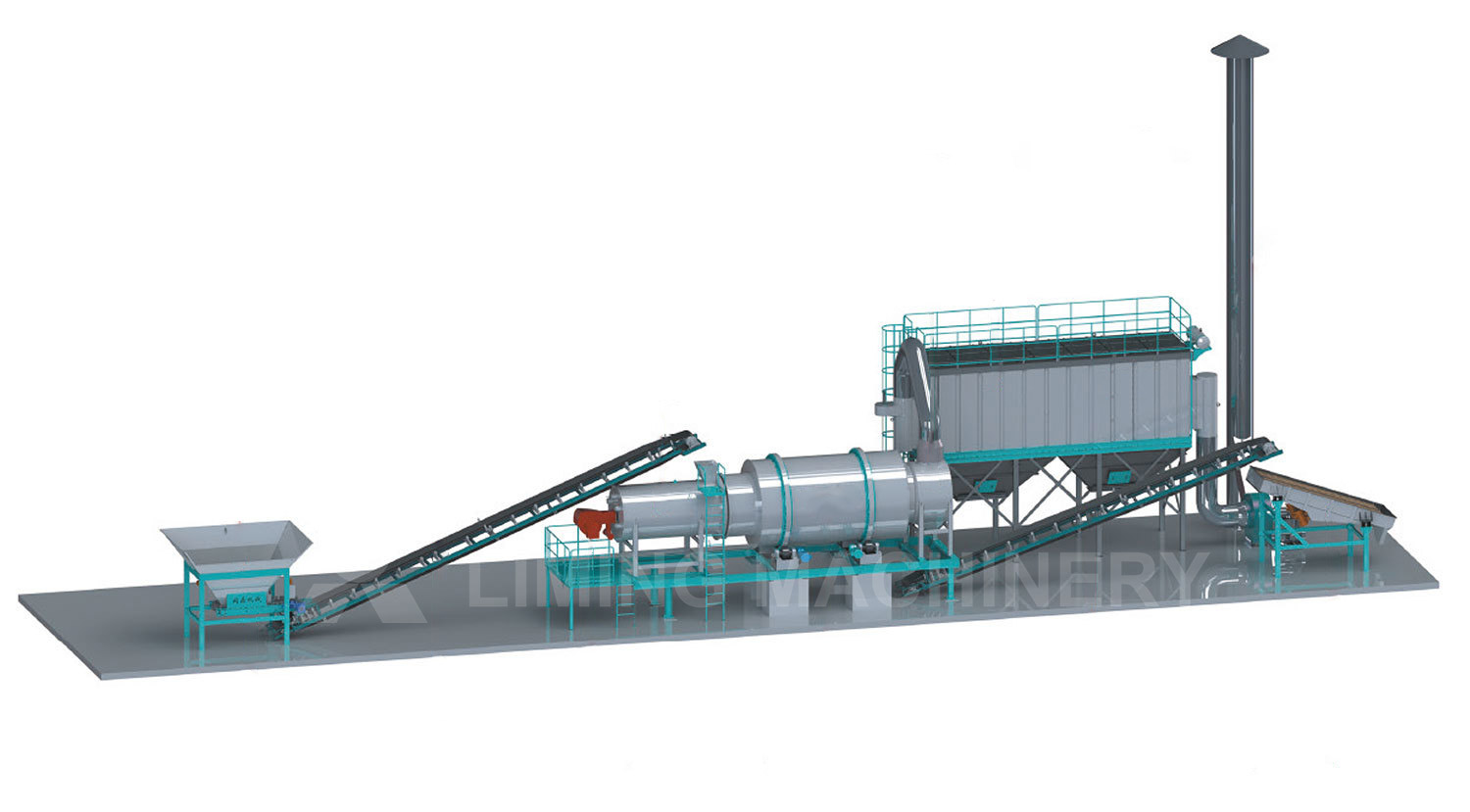

Dryer

The rotary dryer mainly consists of a rotating drum, material retaining rings, a drive system, and supporting devices.The rotary dryer is used for drying materials such as slag, clay, and limestone, primarily in the cement, chemical, metallurgical, and building materials industries. It offers advantages including high drying capacity, smooth operation, low energy consumption, user-friendly operation, and high output.

Applications:

Suitable for cement plants and clinker production lines.

Capacity: 0.5-160T/H

Product Details

Performance Advantages

Safe, reliable and environmental protection: Using high-efficiency pulse dust collector, to reduce dust and noise pollution, excellent results of environmental protection.

Low investment and high efficiency: In the same product fineness and power consumption, the investment cost is lower, recovery cycle is shorter and yield is 45% more than jet mill.

Low loss and high fineness: tear and wear parts use high-quality wear-resistant materials, the serve life is more than a year, final fineness up to D97 ≤ 5μm at one time.

Working Principle

Its working principle involves using well-arranged and alternately angled lifters evenly distributed inside the drum to repeatedly lift and shower moisture-bearing material through the rotating chamber. Hot air currents then extract moisture from the material, converting it into water steam discharged into the atmosphere, thereby achieving drying.

WhatsApp

WhatsApp

Leave message

Leave message