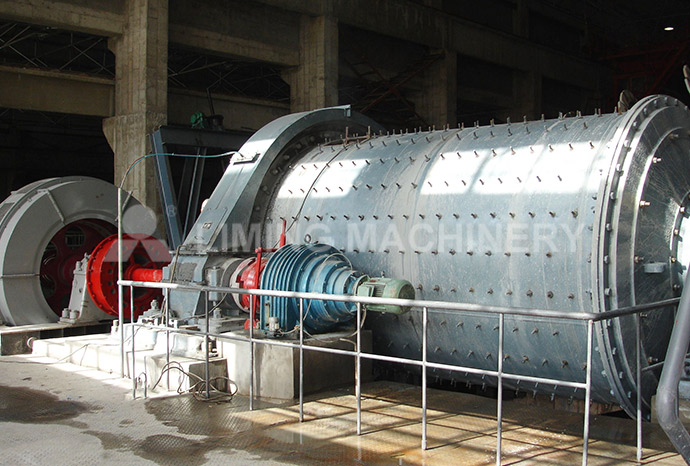

Clinker Ball Mill

Cement clinker is more difficult to grind compared to raw materials, and has higher wear consumption on the lining and steel balls of the ball mill. Therefore, high manganese wear-resistant lining plates are needed with higher wear resistance internally. Ball mills are widely used due to their convenient maintenance and low price.

Applications:

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Capacity: 10-150T/H

Performance Advantages

High grinding efficiency and low maintenance cost.

The product has uniform fineness and smooth.

Low vibration, good equipment sealing, no dust overflow, environment friendly.

Fineness and production capacity can be adjusted within a certain range.

Working Principle

Clinker Ball Mill usually have 2 to 4 chambers, and materials are evenly fed into the first chamber of the ball mill through the feeding screw by the feeding device. The chamber has a stepped lining plate and is filled with grinding media of different specifications. The rotation of the cylinder generates centrifugal force, which brings the grinding media to a certain height and then falls down, causing impact and grinding on the materials. After rough grinding is completed in chamber 1, the material enters the next chamber through the partition plate. This chamber is lined with corrugation or flat lining plates and contains grinding media for further grinding of the material; Powdered materials are discharged through the discharge comb board to complete the grinding process.

WhatsApp

WhatsApp

Leave message

Leave message