Raw Material Vertical Mill

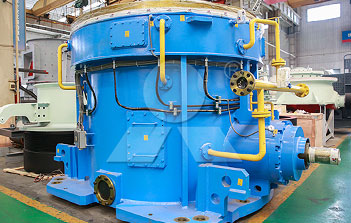

Raw Material Vertical Mill (vertical mill for raw materials)is an energy-saving grinding equipment that integrates drying, grinding, grading, and conveying. It has the characteristics of high grinding efficiency, low power consumption, large feed particle size, low noise, small dust, easy use and maintenance, and low consumption of wear-resistant materials. The comprehensive performance of the product has reached the international advanced level and is mainly used in large-scale raw material processing in industries such as cement, electricity, and metallurgy.

Applications:

cement, electricity, metallurgy, chemical, non-metallic mineral ore and other industries, focus on non-metallic minerals, coal and slag three major areas.

Capacity: 10-400T/H

Input size: 0-55mm

Product Details

Performance Advantages

By adopting advanced material layer grinding principles, the system's power consumption can be reduced by 20-30% compared to ball mills. As the moisture content of the raw materials increases, the energy-saving effect becomes more significant.

Materials can be dried using kiln hot air waste gases, and raw materials with a moisture content of up to 15% can be simultaneously dried and ground.

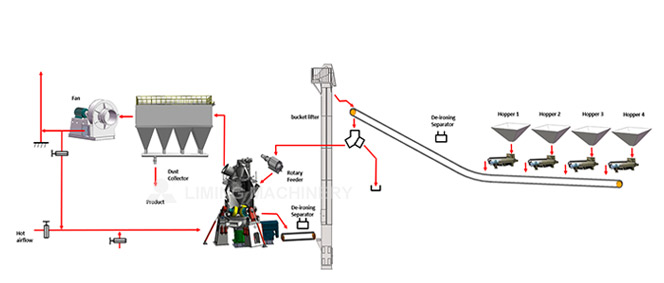

It integrates crushing, drying, grinding, powder classifying and conveying,without the need for additional equipment such as drying, powder selection, and lifting. The workshop area only accounts for 70% of the ball mill system, and the space only occupies 50-60% of it.

The grinding roller and grinding disc do not contact directly during operation, there is no metal impact, and the noise is 20-25 decibels lower than that of the ball mill. The system adopts fully sealed negative pressure operation, with no dust and a clean production environment.

Low wear consumption for the mill and low metal pollution for powder, generally metal wear consumption only 5-10g/t. the grinding roller sleeve can be flipped over for use, which is beneficial for extending its service life and reducing production costs. Easy to operate and maintain.

Grinding products have stable chemical composition, particle size distribution balance, which is beneficial to calcine.

Working Principle

The material falls into the center of the grinding disc through the feeding device. The grinding disc, which rotates at a constant speed, under the centrifugal force to evenly disperse and flatten the raw material, forming a certain thickness of material layer. The material is simultaneously crushed by multiple grinding rollers on the grinding disc. Under the continuous drive of centrifugal force, the material continuously moves towards the outer edge of the grinding disc. When the material leaving the grinding disc encounters hot air entering the mill through the air ring and rises accordingly, it enters the classifier through the middle body of the mill. During this process, the material undergoes sufficient heat exchange with the hot air, and the moisture is quickly evaporated. The powder classifier controls the particle size of the finished product. Particles larger than the specified size are separated and fall back to the grinding disc. Materials that meet the fineness requirements enter the finished product silo through the powder classifier.

WhatsApp

WhatsApp

Leave message

Leave message