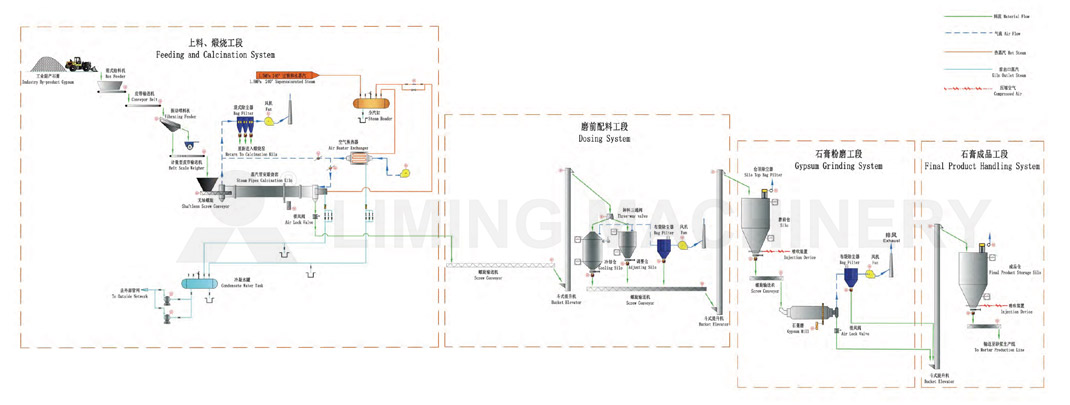

Use a loader to transport gypsum ore raw materials from the raw material pile to the receiving steel hopper. The large gypsum ore is crushed to the required particle size by the crushing equipment, and the materials that meet the particle size requirements are stored in the raw material bin through the conveying equipment. Small pieces of material are metered and transported to the mill for grinding, where the block shaped material is ground into powder to achieve the required fineness for the process. The powder is transported by the conveying equipment to the finished product silo for storage. Subsequently, the powder is uniformly transported to the gypsum powder calcination equipment through the metering feeding device, where the gypsum powder will complete the conversion from dihydrate gypsum to hemihydrate gypsum. After calcination, it is ground and modified by ball mill, cooled by cooling equipment, and then transported to the finished product silo for storage and aging by conveying equipment.