Cement Lime Production Process and Grinding Production Line Configuration

The cement lime production process mainly includes key steps such as raw material mining, crushing, grinding, calcination, and packaging. The specific process is as follows:

1.Raw Material Mining and Transportation:

Limestone is the main raw material. After being mined by blasting, it is transported to the factory by transportation equipment (such as trucks and belt conveyors).

2.Crushing and Pre-homogenization:

Large raw materials such as limestone need to be crushed to a suitable particle size using equipment such as jaw crushers and cone crushers.

The crushed raw materials are homogenized in a pre-homogenization stockpile to ensure stable composition.

3.Raw Meal Preparation:

Grinding: The crushed limestone is mixed with clay, iron ore, etc., in a certain proportion and then ground to the required fineness (usually specific surface area ≥300m²/kg) using equipment such as vertical mills and ball mills.

Homogenization: The ground raw meal is further homogenized in a CF homogenization silo or an IBAU homogenization silo to reduce compositional fluctuations.

4.Calcination (Clinker Calcination)

Preheating and Decomposition: Raw materials are preheated to approximately 900℃ in a preheater, where some carbonates decompose.

Rotary Kiln Calcination: The preheated raw materials enter a rotary kiln, where silicate minerals are formed at a high temperature of 1450℃, producing cement clinker.

5.Cooling and Packaging

Cooling: The clinker is rapidly cooled to below 100℃ in a cooler to recover waste heat.

Packaging: The clinker is mixed with gypsum and admixtures in a specific ratio, then ground to the final fineness (specific surface area ≥350m²/kg) in a cement mill, and shipped in bags or bulk.

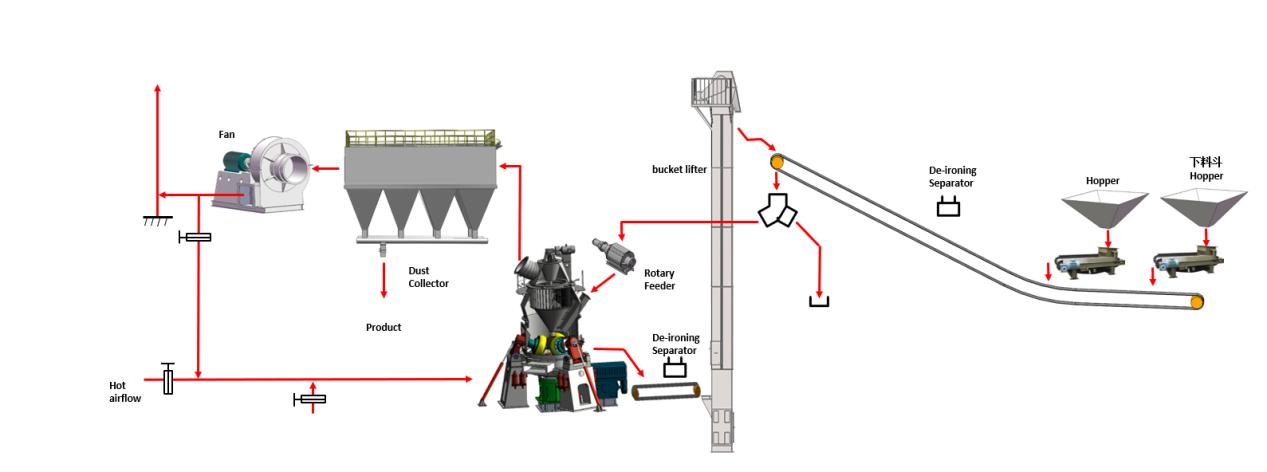

Core Configuration and Process Flow of the Grinding Production Line:

Currently, Liming Heavy Industry's vertical mill has become the mainstream choice for large-scale modern production lines due to its high efficiency. The typical process flow and core configuration are as follows:

1. Core Process Flow

Raw Material Bin -> Feeder -> Vertical Mill -> High-Efficiency Air Classifier -> Pulse Bag Filter -> Finished Product Bin -> Packaging or Bulk

Crushing and Pre-homogenization: Large pieces of limestone/clinker and other raw materials are first crushed to a certain particle size (usually <30mm) and pre-homogenized in the stockpile to ensure stable composition.

Drying and Grinding: Raw materials are fed into the vertical mill via a lock-air feeder. The vertical mill integrates drying, grinding, and air classification. Hot air from the furnace or kiln tail is introduced into the vertical mill to dry materials with moisture content while grinding.

Classification and Collection: The ground material is carried by airflow to the high-efficiency air classifier at the top. Coarse powder is separated and returned to the grinding disc for further grinding, while qualified fine powder is collected by the pulse bag filter as the finished product.

Storage and Shipping: Collected finished products are transported to large steel silos via air conveyor chutes and elevators for storage, and then packaged or shipped in bulk.

2. Key Equipment Selection

Main Unit: Vertical Mill. Compared to traditional ball mills, it reduces power consumption by 20%-30%, has a smaller footprint, lower noise, and stronger drying capacity.

Dust Collection System: High-concentration, explosion-proof pulse bag filter. Emission concentration can be stably kept below 10mg/Nm³, meeting ultra-low emission requirements.

Core Fan: One of the main power-consuming devices in the production line. Modern production lines generally use variable frequency speed control to intelligently adjust air volume and pressure according to operating conditions, achieving energy savings.

Intelligent Control System: A central control system based on PLC and DCS, enabling one-button start/stop, interlocking control, online monitoring, fault alarms, and remote operation and maintenance.

Liming Heavy Industry provides you with complete sets of cement and lime production equipment, including crushing, grinding, and calcination,etc. We are committed to providing customized production line services for our clients, offering guidance throughout the entire process from initial project planning to final commissioning, ensuring that we meet your integrated needs.

CASES

-

>

Coal mill, 200 mesh, D85, 45tph

-

>

50-60t/h Vertical Roller Mill For Limestone

-

>

Silicate Cement Production Line

-

>

Vertical Mill, Process slag, 325mesh, 80-100tph

-

>

Limestone powder production line

-

>

GBFS powder preparation project

-

>

1500t/d Cement Clinker Production Line

-

>

Pulverized Coal Preparation Project

-

>

Ultrafine limestone powder production project

-

>

Electrolytic Aluminum Overhaul Slag Powder-Making Production Line

Learn More

WhatsApp

WhatsApp

Leave message

Leave message